The Background

Digital printing is a process that can use between 4-7 colours to produce an image from an electronic file. This is the best way to print full colour images (more than 4 colours) or logo and images that have a close registration. This image is created using toner or ink in a similar method to that of an office printer. Much like a home or office printer, a commercial digital printing press can use in a powder form (like toner) or in a liquid form, and the ink dries instantly. This means that the printed product can be sent straight to finishing, making the process much less time consuming. The commercial press is also much bigger and faster, offering a higher better print quality and significantly more function.

Digital printing also has no requirement for printing plates, as the PDF artwork is sent directly to the press from the computer, this can also provide a quicker turnaround time, and help to reduce the cost. This also means that shorter runs can be produced without the high cost of lithographic printing. Another benefit of digital printing is that it can be more flexible in the printing of low-resolution graphics, as it is capable of printing images as low as 150dpi (unlike lithography which has a minimum resolution of 300dpi).

There are a variety of methods of digital printing that can be used, depending on the product being printed and the budget.

Variable Data Printing

Variable data printing (otherwise known as VDP) is a form of digital printing which is more customisable, meaning that printed graphics and text can be changed throughout a print run without slowing down a press. This is particularly useful when printing personalised products, as it means that individual names can be printed on each one. This form of printing is most common in the digital marketing industry and has also increased in popularity with the printing or individual mugs, bottles, and badges.

The Process

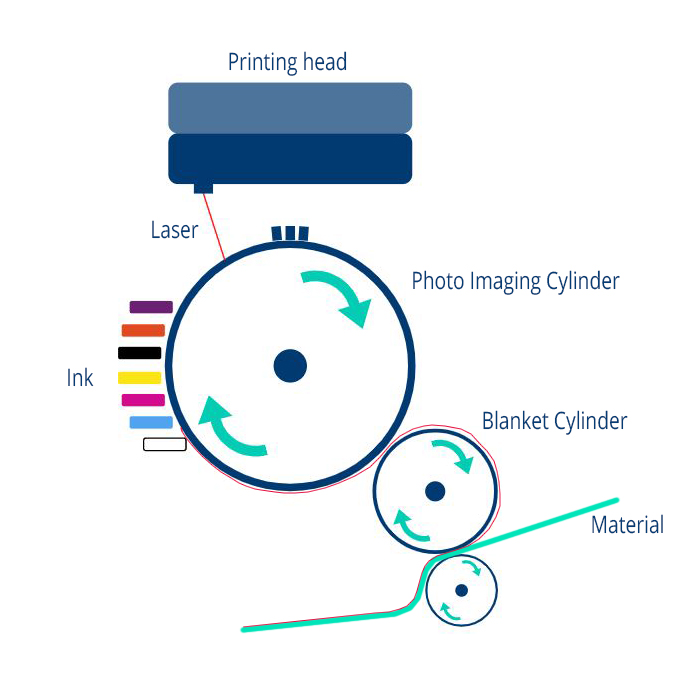

The process shown above is an example of laser printing.

This works by using a silicone photoreceptor belt which is passed under an electrostatic charger to give the belt a negative charge.

A laser then focuses light on specific areas of the belt in order to reverse the charge and create the image.

The inks (which are mixed with an agent to give them a negative charge) are then applied to the belt and stick to the positively charged areas.

For a single colour print, this is them applied directly to the paper.

For full colour printing, each colour is applied separately to the transfer belt, and the image is then applied in its entirety to the paper.